Problem

The circular economy begins in the household. For a variety of water uses in the household, such as flushing toilets, watering the garden and cleaning purposes, drinking water of high quality is mostly used, but this would not be necessary if other forms of industrial or process water were available. What hygienically safe and environmentally compatible possibilities are there for saving drinking water and thus also money? For which areas of application is this process worthwhile and which synergies, e.g. for energy savings, are still possible through grey water use?

Generic Description

Grey water is slightly contaminated water from the shower, bathtub, hand basin or washing machine. In principle, this water is suitable for treatment and further use. As a rule, the grey water is filtered in a biological-mechanical process. The process water thus obtained is hygienically safe and can be used for toilet flushing, irrigation, laundry and commercial purposes. Grey water can be treated using various mechanical, physical or biological processes without chemical additives. The first step of a four-stage biological-mechanical treatment is pre-filtration. The grey water flows through a filter into the first tank, where the water is pre-cleaned and pumped into the second tank. In both tanks, the water is biologically purified by adding oxygen. In the process, microorganisms settle on free-floating foam bodies and clean the water. Sediments are produced and settle in the tanks. They are automatically extracted and discharged into the sewage system. The water is disinfected with UV light disinfection and then pumped into the third tank. The water is now highly safe and ready for further use. Biological water purification is also possible with near-natural solutions such as plant filters, reed planting, mussels or grit beds. Domestic grey water use can be supplemented with rainwater.

Treated grey water can also be used for urban agriculture, as demonstrated in the Roofwaterfarm research project (Million et al. 2018 b, p. 33 ff; König 2018).

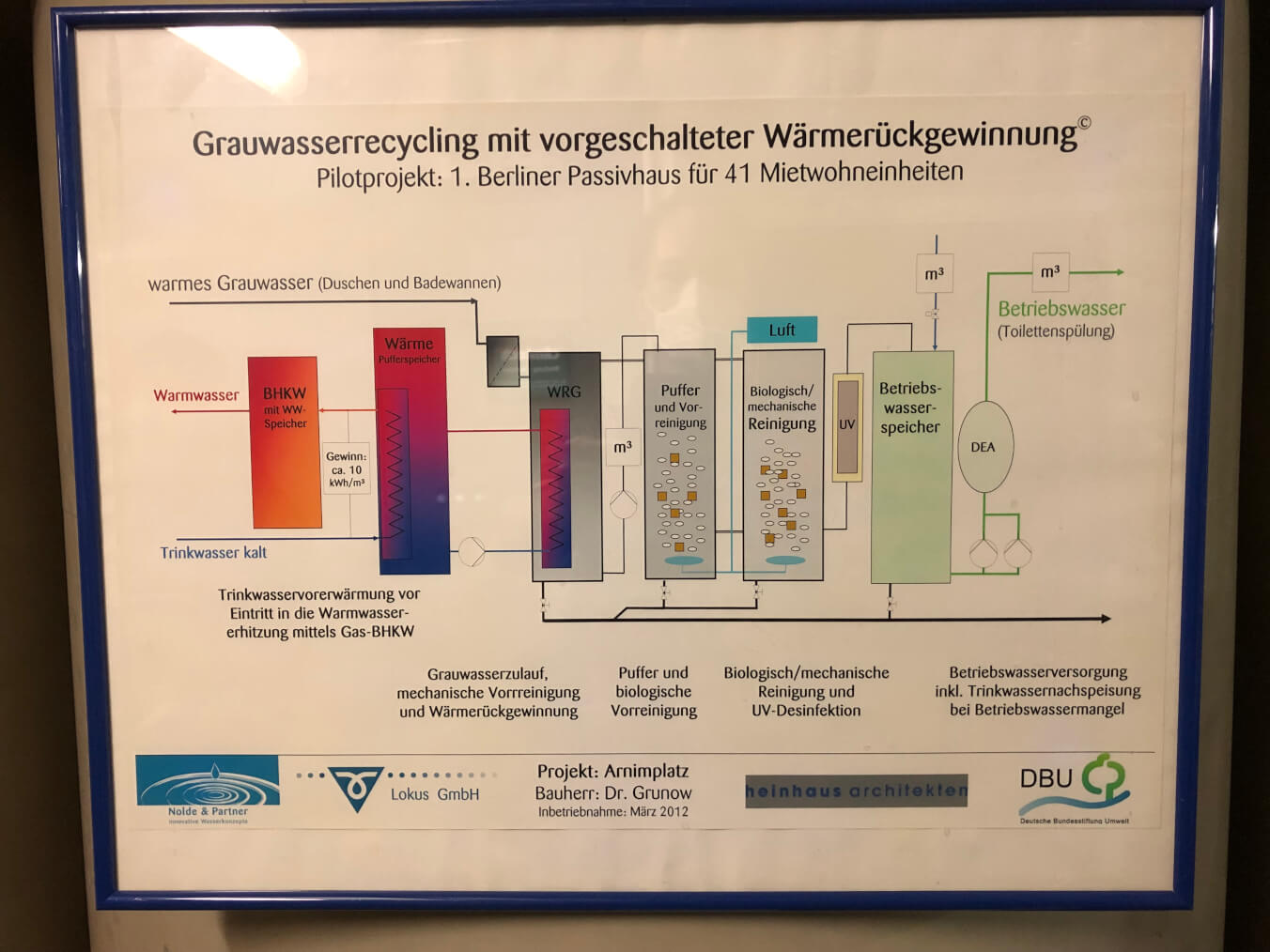

In addition, a system coupling of water and energy recycling can save drinking water, wastewater and thermal energy at the same time without a hygienic risk or loss of comfort for the house occupants (Nolde 2013, König 2019). Using the example of the Berlin “Passive House at Arnimplatz”, waste heat recovery from grey water could also be demonstrated to be economically viable. Since modern Passive Houses require only little heating energy for space heating, most of the heat energy is needed for hot water supply. After use, the warm and usually slightly polluted grey water is discharged unused into the sewage system. The shower or bath water preheated by the grey water through a heat exchanger is heated to a final temperature of approx. 60°C in a further stage by conventional heat exchangers in combination with a solar system or a boiler, thus fulfilling all hygienic requirements (protection against legionella) (Nolde 2013).

Example

“The ufaFabrik Berlin uses filtered grey water on site for toilet flushing. The ufaFabrik needs about 3000 cubic metres of service water per year for flushing toilets and watering green areas. Before the rainwater harvesting system was installed, the only water available for this purpose was precious drinking water that had been purified at great expense by the waterworks. Since the beginning of the 1990s, rainwater from approx. 8,000 sqm of roof surfaces, asphalted paths and squares flows through the sewage system into the water reservoir that used to house the waterworks of the film company. The technical installations of the waterworks were removed and the walls sealed with water glass against evaporation and seepage losses. In the winter of 1997/98, the service water reservoir received a new ceiling construction. With an average annual rainfall of about 500 mm, it is possible to collect 4000 cubic metres of rainwater per year from an area of 8000 square metres – enough for the ufa factory’s service water needs. In a sedimentation basin, stones, sand and mud sink to the bottom; floating particles such as leaves, paper and wood are caught by gravel on the partition wall when they overflow into the second basin. The coarsely cleaned water is pumped into the plant/soil filter as needed and filtered there. Here, the substrate of fine expanded shale removes the remaining suspended particles. Soil organisms in the roots of reeds, rushes, water lilies and bulrushes convert further impurities into minerals, which the plants absorb as fertiliser. Through this treatment, almost all drinking water quality is achieved. A cistern located under the soil filter stores the service water and a pressure boosting system distributes it to the buildings” (ufaFabrik n.y.).

Lessons learned and synergies

Lightly polluted grey water has so far mostly been fed to wastewater treatment plants via the sewage system, but could circulate on site in closed loops, which is more ecologically and economically sustainable.

Nature-based solutions such as constructed wetlands or aerated fixed-bed systems are cost-effective, offer environmental benefits and are generally more resilient, but also require more open space, which leads to conflicting goals in dense urban areas (König 2018, p. 49). Grey water treatment not only saves drinking water, but also reduces wastewater costs, and by using heat exchangers, the residual heat of the grey water can be used to save heating energy. Intelligent monitoring is required for proper system operation, especially in the case of complex system couplings. Architects and building owners are recommended to always provide a second pipe network for greywater collection and service water utilisation in new buildings or refurbishments in order to optimise material flows and save operating costs in conjunction with a greywater recycling system and upstream heat recovery (Nolde 2013, p. 42). Grey water use is particularly worthwhile in larger hotel facilities. In small greywater systems, however, the annual maintenance costs can counteract economic use.

Sources

König, Klaus W. (2018): Aquaponik in Berlin nutzt Grauwasser. Häusliches Abwasser als Ressource. In: TGA Fachplaner Plus, 5/2018, S. 46-50. Accessed on 23.02.2022 from https://www.klauswkoenig.de/images/Grauwasser/aquaponik_bauen+.pdf

König, Klaus W. (2019): Kläranlage und Geldanlage? Häusliches Grauwasser: Wer Wärme zurückholt, erhält Subventionen. In: Bauen Plus, 4/2019, S. 38-42. Accessed on 23.02.2022 from https://klauswkoenig.de/images/waermerueckgewinnung/kl%C3%A4ranlage_bauen+.pdf

Million et al. (ed.) (2018 b): ROOF WATER-FARM – Urbanes Wasser für urbane Landschaft. Universitätsverlag der TU Berlin: Berlin. https://depositonce.tu-berlin.de/bitstream/11303/7413/3/roof_water-farm.pdf

Nolde, Erwin (2013): Dezentrale Abwasserw.rmerückgewinnung in Kombination mit einer Grauwasserrecyclinganlage. Abschlussbericht eines Forschungsprojekts gefördert durch die Deutsche Bundesstiftung Umwelt, Osnabrück. DBU Projekt AZ 28201.

Accessed on 23.02.2022 from https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-28201.pdf

ufaFabrik e.V. (n.y.): Trinkwasser – zum Spülen zu kostbar.

Accessed on 25.02.2022 from https://www.ufafabrik.de/de/10559/trinkwasser-zum-spulen-zu-kostbar.html